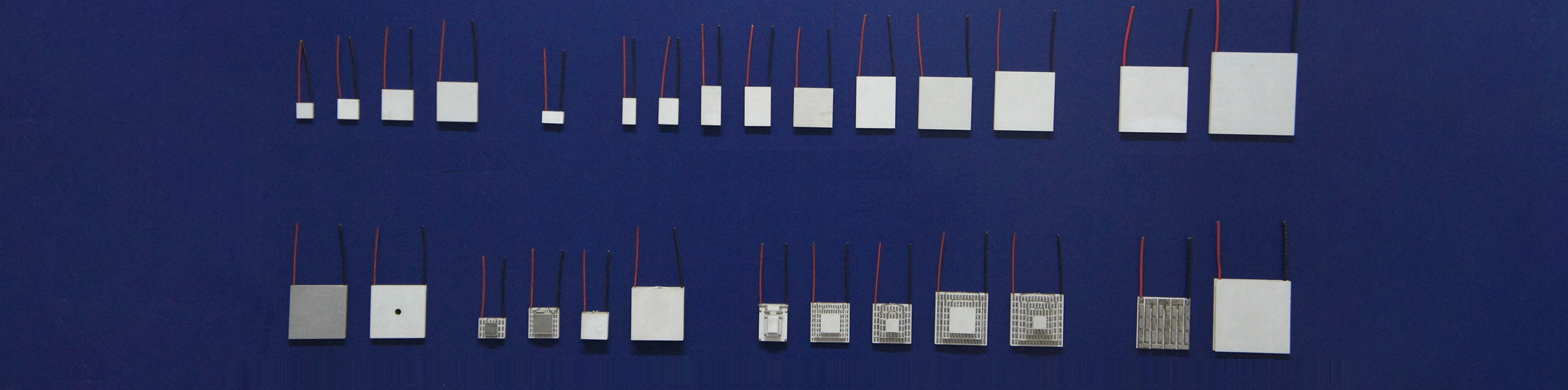

Beijing Huimao Cooling Equipment Co., Ltd. has launched a series of thermoelectric cooling modules, thermoelectric modules, peltier elements, peltier devices, including batch standard thermoelectric cooling modules,TEC modules and customized special thermoelectric modules,peltier modules,peltier elements according to customer needs. There are single-stage thermoelectric modules,peltier devices,TEC modules as well as multi-stage thermoelectric cooling modules,thermoelectric modules,peltier coolers such as two-stage, three-stage to six-stage. Thermoelectric cooling modules(thermoelectric modules,peltier elements) utilize the thermoelectric effect of semiconductors. When direct current passes through a thermocouple formed by connecting two different semiconductor materials in series, the cold end and the hot end respectively absorb and release heat, making them an ideal choice for temperature cycling applications. It does not require any refrigerant, can work continuously, has no pollution source and no rotating parts, and will not produce a rotary effect. In addition, it has no sliding parts, operates without vibration or noise, has a long service life and is easy to install. Thermoelectric cooling modules,TEC modules,peltier modules,thermoelectric modules are widely used in medical, military and laboratory fields where high temperature control accuracy and reliability are required.

How to select the right type is the beginning of the application of thermoelectric modules, thermoelectric cooling modules, TE modules. Only by choosing the thermoelectric cooling module can the expected temperature control target be achieved. Before choosing a Peltier module, TEC module, thermoelectric module, it is necessary to first clarify the cooling requirements, what the target object of the cooling is, what kind of cooling technology to choose, what kind of heat conduction method, what the target temperature is, and how much power can be provided. If you plan to choose thermoelectric cooling modules, thermoelectric module, peltier modules, TEC module, peltier elements from Beijing Huimao Cooling Equipment Co., Ltd., you can determine the required model through the following selection steps.

1. Estimate the heat load

Heat load refers to the amount of heat that needs to be removed to lower the temperature of a cooling target to a specified level under a certain temperature environment, with the unit being W (watt). Heat loads mainly include active loads, passive loads, and their combinations. The active heat load is the heat load generated by the cooling target itself. Passive heat load is the heat load caused by external radiation, convection and conduction. Active load calculation formula

Qactive = V2/R = VI = I2R;

Qactive = Active heat load (W);

V = The voltage applied to the refrigeration target (V);

R = Resistance of the refrigeration target;

I = Current flowing through the cooled target (A)

Radiant heat load is the heat load transferred to the target object through electromagnetic radiation. Calculation formula:

Qrad = F e s A (Tamb4 – Tc4);

Qrad = Radiant heat Load (W);

F = shape factor (worst value = 1);

e = emissivity (worst-case value = 1);

s = Stefan-Boltzmann constant (5.667 X 10-8W/m ² k4);

A = Cooling surface area (m ²);

Tamb = Ambient Temperature (K);

Tc = TEC – Cold end temperature (K).

Convective heat load is the heat load transferred naturally by the fluid passing through the surface of the target object from the outside. The calculation formula is:

Qconv = hA (Tair – Tc);

Qconv = Convective heat Load (W)

h = Convective heat transfer coefficient (W/m ² °C) (typical value of the water plane at one standard atmosphere) = 21.7 W/m ² °C;

A = Surface area (m ²);

Tair = Ambient temperature (°C);

Tc = Cold end temperature (°C);

Conductive heat load is the heat load transferred from the outside through the contact objects on the surface of the target object. The calculation formula is:

Qcond =k A DT/L;

Qcond = Transferred heat load (W);

k = Thermal conductivity of the thermal conductive material (W/m °C);

A = The cross-sectional area of the thermal conductive material (m ²);

L = Length of the heat conduction path (m)

DT = Temperature difference of the heat conduction path (°C) (usually referring to the ambient temperature or heat sink temperature minus the cold end temperature.)

For the combined heat load of convection and conduction, the calculation formula is:

Q passive = (A x DT)/(x/k + 1/h);

Qpassive = Heat load (W);

A = Total surface area of the shell (m2);

x = Thickness of the insulation layer (m)

k = Insulation thermal conductivity (W/m °C);

h = Convective heat transfer coefficient (W/m ² °C)

DT = Temperature difference (°C).

2. Calculate the total heat load

Through the first step, we can calculate the total heat load of the refrigeration target.

Suppose in the actual project, the active heat load is 8W, the radiant heat load is 0.2W, the convective heat load is 0.8W, the conductive heat load is 0W, and the total heat load is 9W.

3. Define temperature

Define the hot end temperature, cold end temperature and refrigeration temperature difference of the refrigeration sheet. Suppose in the actual project, the ambient temperature is 27°C, the cooling target temperature is -8°C, and the cooling temperature difference DT=35°C

Assuming that the total heat load of the cooling target is estimated to be 9W based on the previous estimation, the optimal Qmax can be obtained as 9/0.25=36W, and the maximum Qmax as 9/0.45=20. Search the product catalogue of Beijing Huimao Cooling Equipment Co.,Ltd for thermoelectric cooling modules,peltier modules,peltier devices,peltier elements.TEC modules and find the products with Qmax ranging from 20 to 36.

Post time: Sep-09-2025