The use of thermoelectric module (also known as thermoelectric cooling modules, TEC, or Thermoelectric Cooler) in the photon skin rejuvenation device is mainly to achieve the cooling function, in order to enhance the comfort and safety during the treatment process. Here is a detailed explanation of the thermoelectric cooling modules, thermoelectric modules, TECs, peltier modules in the photon skin rejuvenation device:

1. Working principle

The thermoelectric module is based on the Peltier effect: When a direct current passes through a thermoelectric pair composed of N-type and P-type semiconductor materials, one end absorbs heat (the cold end) and the other end releases heat (the hot end). In the photon skin rejuvenation device:

The cold end is close to the skin or the light-guiding crystal, used for cooling

The hot end is connected to the heat sink (such as a fan or water cooling system), to discharge heat

2. Main functions in the photon skin rejuvenation device Protect the skin

Intense pulsed light (IPL) or laser irradiation generates heat, which may cause burns or discomfort. The cooling pad can rapidly lower the skin temperature and reduce the risk of thermal damage.

Improve comfort

The cooling sensation can significantly alleviate the pain or burning sensation during the treatment, enhancing the user experience.

Enhance efficacy

After the epidermis is cooled, the energy can be more concentrated on the target tissue (such as hair follicles, pigment cells), improving the efficiency of selective photothermal action.

Prevent pigmentation

Effective temperature control can reduce the risk of post-operative post-inflammatory hyperpigmentation (PIH), especially for people with darker skin tones.

3. Common Configuration Methods

Contact cooling: The cooling pad either directly or through a sapphire/silicon optical window contacts the skin

Non-contact cooling: Combined with cold air or gel assistance, but semiconductor cooling remains the core cooling source

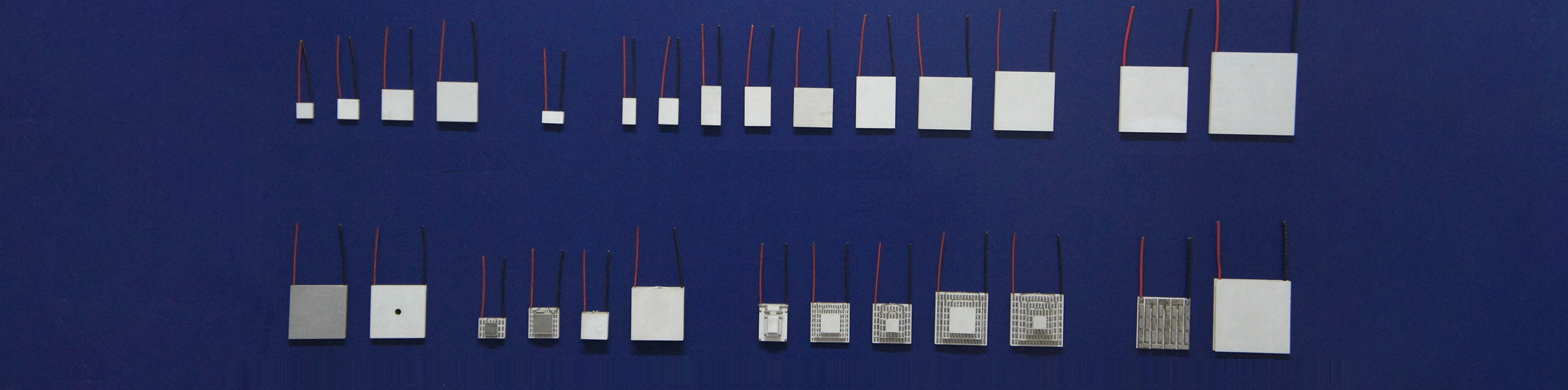

Multi-stage TEC,multi-stage thermoelectric module: High-end equipment may use multiple cooling pads to achieve lower temperatures (such as 0-5℃)

4. Precautions

Power consumption and heat dissipation: Peltier module, TEC module requires a large current, and the hot end must have effective heat dissipation; otherwise, the cooling efficiency will drop sharply or even damage the device

Condensation water issue: If the surface temperature is lower than the dew point, condensation water may form, and waterproof/insulation treatment is required

Life and reliability: Frequent switching or high-temperature environments will shorten the lifespan of TEC module. It is recommended to use industrial-grade components

TES1-17710T125 Specification

Hot side temperature is 30 C,

Imax:10.5 A,

Umax:20.9V

Qmax:124 W

ACR: 1.62 ±10% Ω

Delta T max: > 65 C

Size :bottom 84×34 mm ,top : 80x23mm, height: 2.9mm

Center hole:60x 19 mm

Ceramic plate: 96%Al2O3

Sealed: Sealed by 703 RTV (white color)

Cable : 18 AWG wire temperature resistance 80℃.

Cable length: 100mm , wire strip and tin with Bi Sn solder,10mm

Thermoelectric material: Bismuth Telluride

Post time: Jan-14-2026