The development and application of thermoelectric cooling module ,TEC module, peltier cooler in the field of optoelectronics

Thermoelectric Cooler, thermoelectric module,peltier module (TEC) plays an indispensable role in the field of optoelectronic products with its unique advantages. The following is an analysis of its wide application in optoelectronic products:

I. Core Application Fields and Mechanism of Action

1. Precise temperature control of the laser

• Key requirements: All semiconductor lasers (LDS), fiber laser pump sources, and solid-state laser crystals are extremely sensitive to temperature. Temperature changes can lead to:

• Wavelength drift: Affects the wavelength accuracy of communication (such as in DWDM systems) or the stability of material processing.

• Output power fluctuation: Reduces the consistency of system output.

• Threshold current variation: Reduces efficiency and increases power consumption.

• Shortened lifespan: High temperatures accelerate the aging of devices.

• TEC module,thermoelectric module function: Through a closed-loop temperature control system (temperature sensor + controller +TEC module,TE cooler), the operating temperature of the laser chip or module is stabilized at the optimal point (typically 25°C±0.1°C or even higher precision), ensuring wavelength stability, constant power output, maximum efficiency and extended lifespan. This is the fundamental guarantee for fields such as optical communication, laser processing, and medical lasers.

2. Cooling of photodetectors/infrared detectors

• Key Requirements:

• Reduce dark current: Infrared focal plane arrays (IRFPA) such as photodiodes (especially InGaAs detectors used in near-infrared communication), avalanche photodiodes (APD), and mercury cadmium telluride (HgCdTe) have relatively large dark currents at room temperature, significantly reducing the signal-to-noise ratio (SNR) and detection sensitivity.

• Suppression of thermal noise: The thermal noise of the detector itself is the main factor limiting the detection limit (such as weak light signals and long-distance imaging).

• Thermoelectric cooling module,Peltier module (peltier element) function: Cool the detector chip or the entire package to sub-ambient temperatures (such as -40°C or even lower). Significantly reduce dark current and thermal noise, and significantly improve the sensitivity, detection rate and imaging quality of the device. It is particularly crucial for high-performance infrared thermal imagers, night vision devices, spectrometers, and quantum communication single-photon detectors.

3. Temperature control of precision optical systems and components

• Key requirements: The key components on the optical platform (such as fiber Bragg gratings, filters, interferometers, lens groups, CCD/CMOS sensors) are sensitive to thermal expansion and refractive index temperature coefficients. Temperature changes can cause alterations in the optical path length, focal length drift, and wavelength shift at the center of the filter, leading to deterioration of system performance (such as blurred imaging, inaccurate optical path, and measurement errors).

• TEC module, thermoelectric cooling module Function:

• Active temperature control: Key optical components are installed on a high thermal conductivity substrate, and TEC module(peltier cooler,peltier device),thermoelectric device precisely controls the temperature (maintaining a constant temperature or a specific temperature curve).

• Temperature homogenization: Eliminate the temperature difference gradient within the equipment or between components to ensure the thermal stability of the system.

• Counter environmental fluctuations: Compensate for the impact of external environmental temperature changes on the internal precision optical path. It is widely applied in high-precision spectrometers, astronomical telescopes, photolithography machines, high-end microscopes, optical fiber sensing systems, etc.

4. Performance optimization and lifespan extension of leds

• Key requirements: High-power leds (especially for projection, lighting, and UV curing) generate significant heat during operation. An increase in junction temperature will lead to:

• Decreased luminous efficiency: The electro-optical conversion efficiency is reduced.

• Wavelength shift: Affects color consistency (such as RGB projection).

• Sharp reduction in lifespan: Junction temperature is the most significant factor affecting the lifespan of leds (following the Arrhenius model).

• TEC modules,thermoelectric coolers,thermoelectric modules Function: For LED applications with extremely high power or strict temperature control requirements (such as certain projection light sources and scientific-grade light sources), thermoelectric module, thermoelectric cooling module, peltier device, peltier element can provide more powerful and precise active cooling capabilities than traditional heat sinks, keeping the LED junction temperature within a safe and efficient range, maintaining high brightness output, stable spectrum and ultra-long lifespan.

Ii. Detailed Explanation of the Irreplaceable Advantages of TEC modules thermoelectric modules thermoelectric devices (peltier coolers) in Opto electronic Applications

1. Precise temperature control capability: It can achieve stable temperature control with ±0.01°C or even higher precision, far exceeding passive or active heat dissipation methods such as air cooling and liquid cooling, meeting the strict temperature control requirements of optoelectronic devices.

2. No moving parts and no refrigerant: Solid-state operation, no compressor or fan vibration interference, no risk of refrigerant leakage, extremely high reliability, maintenance-free, suitable for special environments such as vacuum and space.

3. Fast response and reversibility: By changing the current direction, the cooling/heating mode can be switched instantly, with a fast response speed (in milliseconds). It is particularly suitable for dealing with transient thermal loads or applications that require precise temperature cycling (such as device testing).

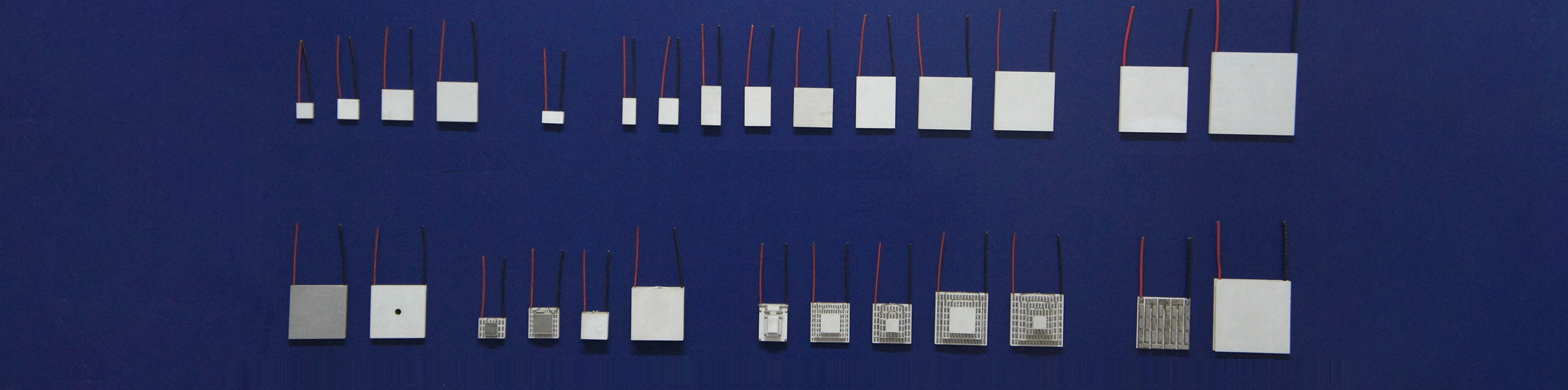

4. Miniaturization and flexibility: Compact structure (millimeter-level thickness), high power density, and can be flexibly integrated into chip-level, module-level or system-level packaging, adapting to the design of various space-constrained optoelectronic products.

5. Local precise temperature control: It can precisely cool or heat specific hotspots without cooling the entire system, resulting in a higher energy efficiency ratio and a more simplified system design.

Iii. Application Cases and Development Trends

• Optical modules: Micro TEC module(micro thermoelectric cooling module, thermoelectric cooling module cooling DFB/EML lasers are commonly used in 10G/25G/100G/400G and higher rate pluble optical modules (SFP+, QSFP-DD, OSFP) to ensure eye pattern quality and bit error rate during long-distance transmission.

• LiDAR: Edge-emitting or VCSEL laser light sources in automotive and industrial LiDAR require TEC modules thermoelectric cooling modules, thermoelectric coolers, peltier modules to ensure pulse stability and ranging accuracy, especially in scenarios that demand long-distance and high-resolution detection.

• Infrared thermal imager: The high-end uncooled micro-radiometer focal plane array (UFPA) is stabilized at the operating temperature (typically ~32°C) through a single or multiple TEC module thermoelectric cooling module stages, reducing temperature drift noise; Refrigerated medium-wave/long-wave infrared detectors (MCT, InSb) require deep cooling (-196°C is achieved by Stirling refrigerators, but in miniaturized applications, TEC module thermoelectric module ,peltier module can be used for pre-cooling or secondary temperature control).

• Biological fluorescence detection/Raman spectrometer: Cooling the CCD/CMOS camera or photomultiplier tube (PMT) greatly enhances the detection limit and imaging quality of weak fluorescence/Raman signals.

• Quantum optical experiments: Provide a low-temperature environment for single-photon detectors (such as superconducting nanowire SNSPD, which requires extremely low temperatures, but Si/InGaAs APD is commonly cooled by TEC Module, thermoelectric cooling module, thermoelectric module,TE cooler) and certain quantum light sources.

• Development trend: Research and development of thermoelectric cooling module, thermoelectric device, TEC module with higher efficiency (increased ZT value), lower cost, smaller size and stronger cooling capacity; More closely integrated with advanced packaging technologies (such as 3D IC, Co-Packaged Optics); Intelligent temperature control algorithms optimize energy efficiency.

Thermoelectric cooling modules, thermoelectric coolers, thermoelectric modules, peltier elements, peltier devices have become the core thermal management components of modern high-performance optoelectronic products. Its precise temperature control, solid-state reliability, rapid response, and small size and flexibility effectively address key challenges such as the stability of laser wavelengths, the improvement of detector sensitivity, the suppression of thermal drift in optical systems, and the maintenance of high-power LED performance. As optoelectronic technology evolves towards higher performance, smaller size and wider application, TECmodule,peltier cooler,peltier module will continue to play an irreplaceable role, and its technology itself is also constantly innovating to meet increasingly demanding requirements

Post time: Jun-03-2025