The new development direction of the thermoelectric cooling industry

Thermoelectric coolers, also known as thermoelectric cooling modules, have irreplaceable advantages in specific fields due to their features such as no moving parts, precise temperature control, small size, and high reliability. In recent years, there has been no disruptive breakthrough in basic materials in this field, but significant progress has been made in material optimization, system design, and application expansion.

The following are several major new development directions:

I. Advances in Core Materials and Devices

Continuous optimization of the performance of thermoelectric materials

Optimization of traditional materials (Bi₂Te₃ -based) : Bismuth tellurium compounds remain the best-performing materials near room temperature. The current research focus lies in further enhancing its thermoelectric merit value through processes such as nanosizing, doping, and texturing. For instance, by manufacturing nanowires and superlattice structures to enhance phonon scattering and reduce thermal conductivity, efficiency can be improved without significantly affecting electrical conductivity.

Exploration of new materials: Although not yet commercially available on a large scale, researchers have been exploring new materials such as SnSe, Mg₃Sb₂, and CsBi₄Te₆, which may have higher potential than Bi₂Te₃ in specific temperature zones, offering the possibility of future performance leaps.

Innovation in device structure and integration process

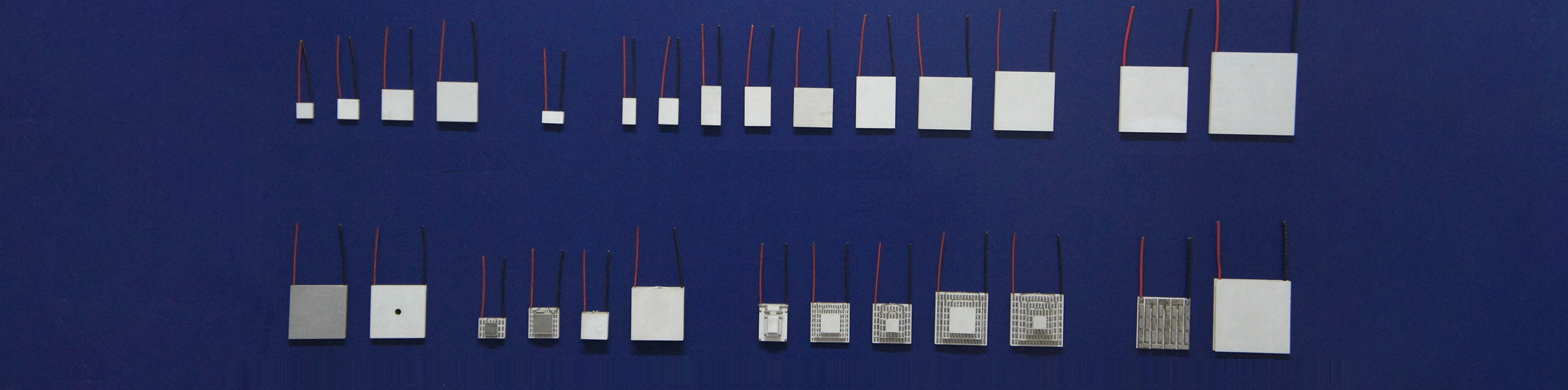

Miniaturization and arrapping: To meet the heat dissipation requirements of micro-devices such as consumer electronics (like mobile phone heat dissipation back clips) and optical communication devices, the manufacturing process of micro-TEC(micro thermoelectric cooling modules,Miniature thermoelectric modules) is becoming increasingly sophisticated. It is possible to manufacture peltier modules,peltier coolers,peltier devices ,thermoelectric devices with a size of only 1×1 mm or even smaller, and they can be flexibly integrated into arrays to achieve precise local cooling.

Flexible TEC module(peltier module): This is an emerging hot topic. By using technologies such as printed electronics and flexible materials, non-planar TEC modules, peltier devices that can be bent and adhered are manufactured. This has broad prospects in fields such as wearable electronic devices and local biomedicine (such as portable cold compresses).

Multi-level structure optimization: For scenarios requiring a greater temperature difference, multi-stage TEC module, multi stage thermoelectric cooling modules remains the primary solution. Current progress is reflected in structural design and bonding processes, aiming to reduce inter-stage thermal resistance, enhance overall reliability and the maximum temperature difference.

Ii. Expansion of System-level Applications and Solutions

This is currently the most dynamic field where new developments can be directly observed.

The co-evolution of hot-end heat dissipation technology

The key factor restricting the performance of TEC module ,thermoelectric module, peltier module is often the heat dissipation capacity at the hot end. The improvement of TEC performance is mutually reinforcing with the development of high-efficiency heat sink technology.

Combined with VC vapor chambers/heat pipes: In the field of consumer electronics, TEC module, peltier device is often combined with vacuum chamber vapor chambers. TEC module, peltier cooler is responsible for actively creating the low-temperature zone, while VC efficiently diffuses heat from the hot end of TEC module, peltier element to the larger heat dissipation fins, forming a system solution of “active cooling + efficient heat conduction and removal”. This is a new trend in heat dissipation modules for gaming phones and high-end graphics cards.

Combined with liquid cooling systems: In fields such as data centers and high-power lasers, TEC module is combined with liquid cooling systems. By taking advantage of the extremely high specific heat capacity of liquids, the heat at the hot end of TEC module thermoelectric module is removed, achieving an unprecedentedly efficient cooling capacity.

Intelligent control and energy efficiency management

Modern thermoelectric cooling systems are increasingly integrating high-precision temperature sensors and PID/PWM controllers. By adjusting the input current/voltage of the thermoelectric module, TEC module, peltier module in real time through algorithms, a temperature stability of ±0.1℃ or even higher can be achieved, while avoiding overcharge and oscillation and saving energy.

Pulse operation mode: For some applications, using pulse power supply instead of continuous power supply can meet the instantaneous cooling requirements while significantly reducing overall energy consumption and balancing the heat load.

Iii. Emerging and High-Growth application Fields

Heat dissipation for consumer electronics

Gaming phones and e-sports accessories: This is one of the biggest growth points in the thermoelectric cooling modules, TEC modules, pletier modules market in recent years. The active cooling back clip is equipped with a built-in thermoelectric modules (TEC modules), which can directly suppress the temperature of the phone’s SoC below the ambient temperature, ensuring continuous high-performance output during gaming.

Laptops and desktops: Some high-end laptops and graphics cards (such as NVIDIA RTX 30/40 series reference cards) have begun to try integrating TEC modules, thermoelectric modules to assist in cooling the core chips.

Optical communication and data centers

5G/6G optical modules: The lasers (DFB/EML) in high-speed optical modules are extremely sensitive to temperature and require TEC for precise constant temperature (usually within ±0.5℃) to ensure wavelength stability and transmission quality. As data rates evolve towards 800G and 1.6T, the demand and requirements for TEC modules thermoelectric mdoules peltier coolers,peltier elements are both increasing.

Local cooling in data centers: Focusing on hotspots such as CPUS and GPUS, using TEC module for targeted enhanced cooling is one of the research directions for improving energy efficiency and computing density in data centers.

Automotive electronics

Vehicle-mounted lidar: The core laser emitter of lidar requires a stable operating temperature. TEC is a key component that ensures its normal operation in the harsh vehicle-mounted environment (-40℃ to +105℃).

Intelligent cockpits and high-end infotainment systems: With the surging computing power of in-vehicle chips, their heat dissipation demands are gradually aligning with those of consumer electronics. TEC module ,TE cooler is expected to be applied in future high-end vehicle models.

Medical and life sciences

Portable medical devices such as PCR instruments and DNA sequencers require rapid and precise temperature cycling, and TEC,peltier module is the core temperature control component. The trend of miniaturization and portability of equipment has driven the development of micro and efficient TEC, peltier cooler.

Beauty devices: Some high-end beauty devices utilize the Peltier effect of TEC ,peltier device to achieve precise cold and hot compress functions.

Aerospace and special environments

Infrared detector cooling: In military, aerospace and scientific research fields, infrared detectors need to be cooled to extremely low temperatures (such as below -80℃) to reduce noise. Multi-stage TEC module,multi-stage peltier module, multi-stage thermoelectric module is a miniaturized and highly reliable solution to achieve this goal.

Satellite payload temperature control: Providing a stable thermal environment for precision instruments on satellites.

Iv. Challenges Faced and Future Prospects

The core challenge: Relatively low energy efficiency remains the biggest shortcoming of TEC module peltier module(thermoelectric module)compared to traditional compressor cooling. Its thermoelectric cooling efficiency is far lower than that of the Carnot cycle.

Future outlook

Material breakthrough is the ultimate goal: if new materials with a thermoelectric superiority value of 3.0 or higher near room temperature can be discovered or synthesized (currently, commercial Bi₂Te₃ is approximately 1.0), it will trigger a revolution in the entire industry.

System integration and intelligence: Future competition will shift more from “individual TEC performance” to the capability of an overall system solution of “TEC+ heat dissipation + control”. Combining with AI for predictive temperature control is also a direction.

Cost reduction and market penetration: With the maturation of manufacturing processes and large-scale production, TEC’s costs are expected to further decline, thereby penetrating into more mid-range and even mass markets.

In summary, the global thermoelectric cooler industry is currently in a stage of application-driven and collaborative innovation development. Although there have been no revolutionary changes in the basic materials, through the advancement of engineering technology and the deep integration with upstream and downstream technologies, TEC module Peltier module, peltier cooler is finding its irreplaceable position in an increasing number of emerging and high-value fields, demonstrating strong vitality.

Post time: Oct-30-2025