Peltier cooling (thermoelectric cooling technology based on the Peltier effect) has become one of the core technologies of the temperature control system for PCR (polymerase chain reaction) instruments due to its rapid reaction, precise temperature control, and compact size, profoundly influencing the efficiency, accuracy, and application scenarios of PCR. The following is a detailed analysis of the specific applications and advantages of thermoelectric cooling(peltier cooling) starting from the core requirements of PCR:

I. Core Requirements for Temperature Control in PCR Technology

The core process of PCR is a repetitive cycle of denaturation (90-95℃), annealing (50-60℃), and extension (72℃), which has extremely strict requirements for the temperature control system.

Rapid temperature rise and fall: Shorten the time of a single cycle (for example, it takes only a few seconds to drop from 95℃ to 55℃), and enhance reaction efficiency;

High-precision temperature control: A deviation of ±0.5℃ in annealing temperature may lead to non-specific amplification, and it should be controlled within ±0.1℃.

Temperature uniformity: When multiple samples react simultaneously, the temperature difference between sample Wells should be ≤0.5℃ to avoid result deviation.

Miniaturization adaptation: Portable PCR (such as on-site testing POCT scenarios) should be compact in size and free of mechanical wear parts.

II. Core Applications of thermoelectric cooling in PCR

The thermoelectric Cooler TEC, Thermoelectric cooling module, peltier module achieves “bidirectional switching of heating and cooling” through direct current, perfectly matching the temperature control requirements of PCR. Its specific applications are reflected in the following aspects:

1. Rapid temperature rise and fall: Shorten reaction time

Principle: By changing the direction of the current, TEC module, thermoelectric module ,peltier device can quickly switch between the “heating” (when the current is forward, the heat-absorbing end of TEC module ,peltier module becomes the heat-releasing end) and “cooling” (when the current is reverse, the heat-releasing end becomes the heat-absorbing end) modes, with a response time usually less than 1 second.

Advantages: Traditional refrigeration methods (such as fans and compressors) rely on heat conduction or mechanical movement, and the heating and cooling rates are usually less than 2℃/s. When TEC is combined with high thermal conductivity metal blocks (such as copper and aluminum alloy), it can achieve a heating and cooling rate of 5-10℃/s, reducing the single PCR cycle time from 30 minutes to less than 10 minutes (such as in rapid PCR instruments).

2. High-precision temperature control: Ensuring amplification specificity

Principle: The output power (heating/cooling intensity) of TEC module ,thermoelectric cooling module, thermoelectric module is linearly correlated with the current intensity. Combined with high-precision temperature sensors (such as platinum resistance, thermocouple) and a PID feedback control system, the current can be adjusted in real time to achieve precise temperature control.

Advantages: The temperature control accuracy can reach ±0.1℃, which is much higher than that of traditional liquid bath or compressor refrigeration (±0.5℃). For instance, if the target temperature during the annealing stage is 58℃, TEC module , thermoelectric module ,peltier cooler, peltier element can stably maintain this temperature, avoiding non-specific binding of primers due to temperature fluctuations and significantly enhancing amplification specificity.

3. Miniaturized design: Promoting the development of portable PCR

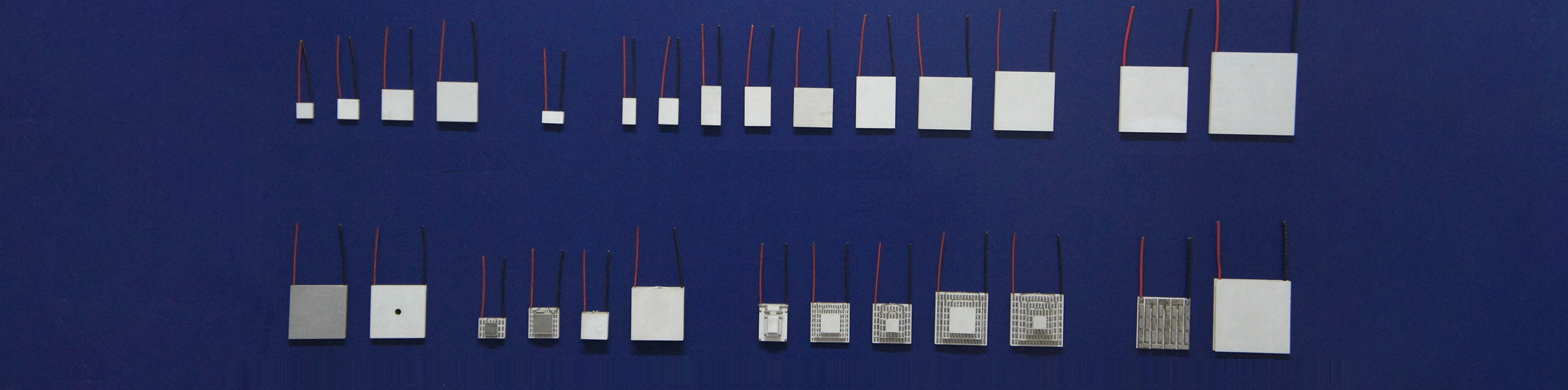

Principle: The volume of TEC module ,peltier element,peltier device is only a few square centimeters (for example, a 10×10mm TEC module, thermoelectric cooling module, peltier module can meet the requirements of a single sample), it has no mechanical moving parts (such as the piston of the compressor or the fan blades), and does not require refrigerant.

Advantages: When traditional PCR instruments rely on compressors for cooling, their volume is usually over 50L. However, portable PCR instruments using thermoelectric cooling module, thermoelectric module, peltier module,TEC module can be reduced to less than 5L (such as hand-held devices), making them suitable for field testing (such as on-site screening during epidemics), clinical bedside testing, and other scenarios.

4. Temperature uniformity: Ensure consistency among various samples

Principle: By arranging multiple sets of TEC arrays (such as 96 micro TECs corresponding to a 96-well plate), or in combination with heat-sharing metal blocks (high thermal conductivity materials), the temperature deviations caused by individual differences in TECs can be offset.

Advantages: The temperature difference between sample Wells can be controlled within ±0.3℃, avoiding amplification efficiency differences caused by inconsistent temperatures between edge Wells and central Wells, and ensuring the comparability of sample results (such as the consistency of CT values in real-time fluorescence quantitative PCR).

5. Reliability and maintainability: Reduce long-term costs

Principle: TEC has no wearing parts, has a lifespan of over 100,000 hours, and does not require regular replacement of refrigerants (such as Freon in compressors).

Advantages: The average lifespan of a PCR instrument cooled by a traditional compressor is approximately 5 to 8 years, while the TEC system can extend it to over 10 years. Moreover, maintenance only requires cleaning the heat sink, significantly reducing the operation and maintenance costs of the equipment.

III. Challenges and Optimizations in Applications

Semiconductor cooling is not perfect in PCR and requires targeted optimization:

Heat dissipation bottleneck: When TEC is cooling, a large amount of heat accumulates at the heat release end (for example, when the temperature drops from 95℃ to 55℃, the temperature difference reaches 40℃, and the heat release power increases significantly). It is necessary to pair it with an efficient heat dissipation system (such as copper heat sinks + turbine fans, or liquid cooling modules), otherwise it will lead to a decrease in cooling efficiency (and even overheating damage).

Energy consumption control: Under large temperature differences, the TEC energy consumption is relatively high (for example, the TEC power of a 96-well PCR instrument can reach 100-200W), and it is necessary to reduce ineffective energy consumption through intelligent algorithms (such as predictive temperature control).

Iv. Practical Application Cases

At present, mainstream PCR instruments (especially real-time fluorescence quantitative PCR instruments) have generally adopted semiconductor cooling technology, for example:

Laboratory-grade equipment: A 96-well fluorescence quantitative PCR instrument of a certain brand, featuring TEC temperature control, with a heating and cooling rate of up to 6℃/s, a temperature control accuracy of ±0.05℃, and supporting 384-well high-throughput detection.

Portable device: A certain handheld PCR instrument (weighing less than 1kg), based on TEC design, can complete the detection of the novel coronavirus within 30 minutes and is suitable for on-site scenarios such as airports and communities.

Summary

Thermoelectric cooling, with its three core advantages of rapid reaction, high precision and miniaturization, has solved the key pain points of PCR technology in terms of efficiency, specificity and scene adaptability, becoming the standard technology for modern PCR instruments (especially rapid and portable devices), and promoting PCR from the laboratory to broader application fields such as clinical bedside and on-site detection.

TES1-15809T200 for PCR machine

Hot side temperature: 30 C,

Imax : 9.2A,

Umax: 18.6V

Qmax:99.5 W

Delta T max: 67 C

ACR:1.7 ±15% Ω (1.53 to 1.87 Ohm)

Size : 77×16.8×2.8mm

Post time: Aug-13-2025