In the future, the demand for thermoelectric cooling modules, thermoelectric coolers (TECs) in the new energy field will exhibit a rapid, structural, and multi-scenario-driven growth trend. Based on the current industry trends, policy orientations, and technological advancements, it is expected that by 2030, new energy-related applications will become the largest growth engine in the peltier modules,thermoelectric module,TEC ,TEC modules high-end market. Here is the detailed analysis.

I. Core Driving Factors

1. Explosive Penetration of New Energy Vehicles

Global sales of new energy vehicles have increased from approximately 14 million in 2023 to over 50 million by 2030 (IEA forecast), with China accounting for more than 50%.

Each high-end new energy vehicle typically carries 2-5 TEC modules(thermoelectric cooling modules ,peltier elements) (for lidar, battery temperature control, cabin electronics, etc.), and L4-level autonomous driving models can have more than 8 of them.

2. Popularization of Advanced Intelligent Driving

From 2025, intelligent driving platforms with 800 TOPS or more will become standard equipment for mid-to-high-end vehicles. The accompanying lidar, millimeter-wave radar, and AI chips all require TEC module ,thermoelectric module, peltier module, TE device TEC temperature control.

A single 1550nm lidar requires 1-2 Micro-TEC module, Micro-thermoelectric module .

3. Solid-State Batteries Approaching Industrialization

Solid-state batteries are more sensitive to temperature windows (with a narrow operating temperature range and concentrated heat generation during fast charging), and traditional liquid cooling cannot meet the requirements. TEC point temperature control becomes a necessity.

Nidec, Toyota, etc. have integrated thermoelectric modules, TEC modules in their solid-state prototype battery packs.

4. Upgrading of Energy Storage Safety Standards

The “Electrochemical Energy Storage Station Safety Regulations” in China mandate constant temperature protection for key components of BMS, promoting the application of TEC,peltier modules, peltier devices, peltier coolers in large-scale energy storage and industrial commercial energy storage.

III. Chinese Market: Accelerated Demand Release for Domestic Substitution

2024 demand for TEC, thermoelectric modules ,TEC modules,thermoelectric cooling modules,peltier modules,peltier elements in China’s new energy vehicles: approximately 18 million pieces (including consumer and automotive-grade)

Expected demand in 2030: over 120 million pieces per year, with the proportion of automotive-grade increasing from <10% to 35%+

The domesticization rate will increase from less than 15% in 2024 (for high-end Micro-TEC, micro thermoelectric module, micro peltier module, micro-peltier devices) to over 50% in 2030, mainly benefiting from:

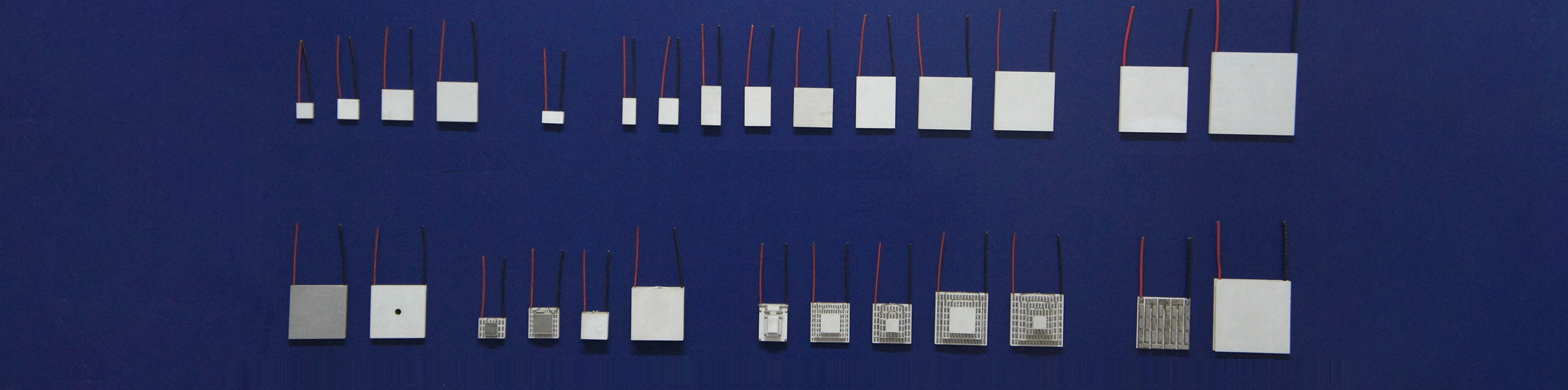

Some Chinese thermoelectric cooling module, thermoelectric modules , peltier modules , peltier cooler manufacturers have achieved mass production of ultra-thin microthermoelectric cooling modules, Micro-peltier modules ,micro peltier elements, Micro-TEC (0.5mm).

Entering the supply chains of Huawei, NIO, XPeng, Speedtronic, etc.;

The cost is 20–30% lower than that of Japanese thermoelectric module for manufacturers (Ferrotec, KELK).

The demand for thermoelectric cooling modules,thermoelectric modules,peltier modules (TEC MODULES) in the new energy sector has shifted from being an “optional accessory” to a “necessity for performance and safety”. Under the triple waves of electrification, intelligence, and safety, Thermoelectric modules, Peltier elements, Pleltier devices, TEC MODULES, with their precise, quiet, reliable, and programmable features, will witness a golden growth period in the next five years. If Chinese enterprises can continuously break through in the three major aspects of vehicle-grade certification, material costs, and system integration, they are expected to occupy a dominant position in the global new energy TEC supply chain.

TES1-03104T125 center hole Specification

Hot side temperature: 30C,

Imax: 4A,

Umax: 3.66V

Qmax:8.68W

ACR: 0.75 ± 0.1 Ω

Delta T max: > 64 C

Size : 18x18x3.2mm , center hole diameter:8mm

Wire: 20AWG PVC wire

Post time: Jan-24-2026