Thermoelectric cooling modules applications

The core of the thermoelectric cooling application product is the thermoelectric cooling module. According to the characteristics, weaknesses and application range of the thermoelectric stack, the following problems should be determined when selecting the stack:

1. Determine the working state of the thermoelectric cooling elements. According to the direction and size of the working current, you can determine the cooling, heating and constant temperature performance of the reactor, although the most commonly used is the cooling method, but should not ignore its heating and constant temperature performance.

2, Determine the actual temperature of the hot end when cooling. Because the reactor is a temperature difference device, to achieve the best cooling effect, the reactor must be installed on a good radiator, according to the good or bad heat dissipation conditions, determine the actual temperature of the thermal end of the reactor when cooling, it should be noted that due to the influence of temperature gradient, the actual temperature of the thermal end of the reactor is always higher than the surface temperature of the radiator, usually less than a few tenths of a degree, more than a few degrees, ten degrees. Similarly, in addition to the heat dissipation gradient at the hot end, there is also a temperature gradient between the cooled space and the cold end of the reactor.

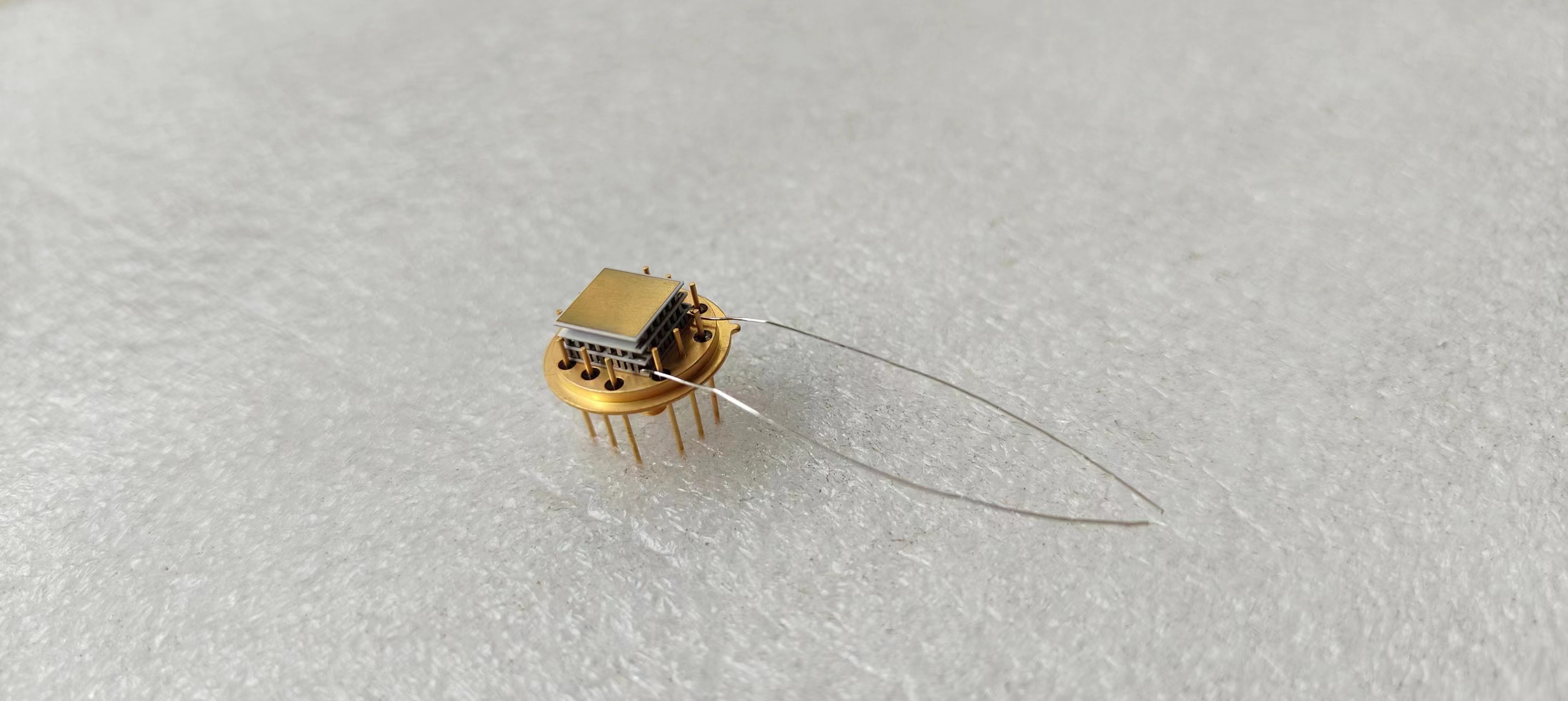

3, Determine the working environment and atmosphere of the reactor. This includes whether the TEC modules, thermoelectric cooling modules to work in a vacuum or in an ordinary atmosphere, dry nitrogen, stationary or moving air and the ambient temperature, from which thermal insulation (adiabatic) measures are taken into account and the effect of heat leakage is determined.

4. Determine the working object of the thermoelectric elements and the size of the thermal load. In addition to the influence of the temperature of the hot end, the minimum temperature or maximum temperature difference that the TEC N,P elements can achieve is determined under the two conditions of no-load and adiabatic, in fact, the peltier N,P elements can not be truly adiabatic, but also must have a thermal load, otherwise it is meaningless.

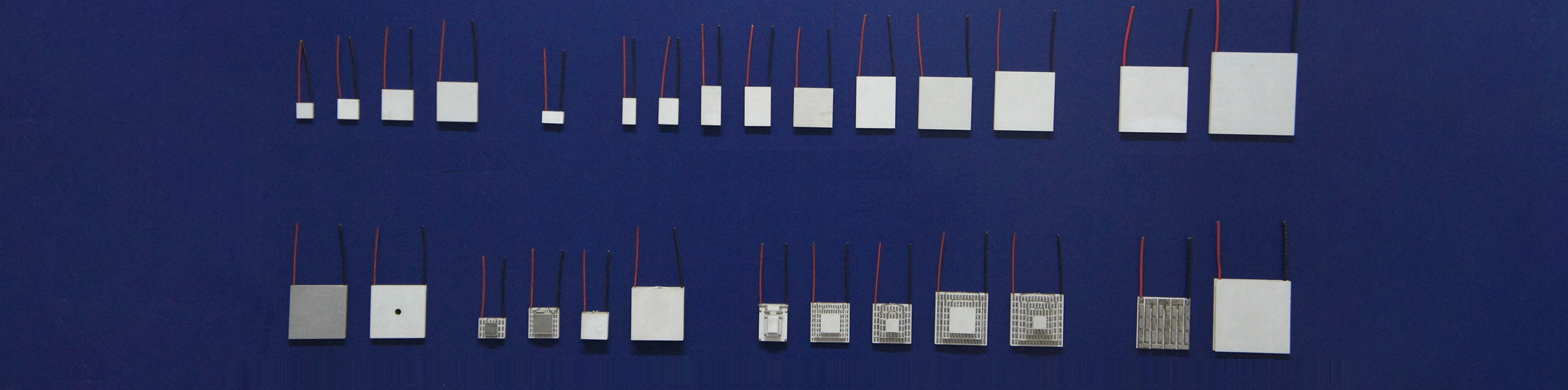

5. Determine the level of the thermoelectric module,TEC module (peltier elements). The selection of the reactor series must meet the requirements of the actual temperature difference, that is, the nominal temperature difference of the reactor must be higher than the actual required temperature difference, otherwise it cannot meet the requirements, but the series can not be too much, because the price of the reactor is greatly improved with the increase of the series.

6. Specifications of the thermoelectric N,P elements. After the series of the peltier device N,P element is selected, the specifications of the peltier N,P elements can be selected, especially the working current of the peltier cooler N,P elements. Because there are several kinds of reactors that can meet the temperature difference and cold production at the same time, but due to different working conditions, the reactor with the smallest working current is usually selected, because the supporting power cost is small at this time, but the total power of the reactor is the determining factor, the same input power to reduce the working current has to increase the voltage (0.1v per pair of components), so the logarithm of components has to increase.

7. Determine the number of N,P elements. This is based on the total cooling power of the reactor to meet the temperature difference requirements, it must ensure that the sum of the reactor cooling capacity at the operating temperature is greater than the total power of the thermal load of the working object, otherwise it can not meet the requirements. The thermal inertia of the stack is very small, no more than one minute under no-load, but because of the inertia of the load (mainly due to the heat capacity of the load), the actual working speed to reach the set temperature is much greater than one minute, and as long as several hours. If the working speed requirements are greater, the number of piles will be more, the total power of the thermal load is composed of the total heat capacity plus the heat leakage (the lower the temperature, the greater the heat leakage).

The above seven aspects are the general principles to be considered when choosing thermoelectric module N,P peltier elements, according to which the original user should first choose the thermoelectric cooling modules,peltier cooler,TEC module according to the requirements.

(1)Confirm the use of ambient temperature Th ℃

(2) The low temperature Tc ℃ reached by the cooled space or object

(3) Known thermal load Q (thermal power Qp, heat leakage Qt) W

Given Th, Tc and Q, the required Thermoelectric cooler N,P elements and the number of TEC N,P elements can be estimated according to the characteristic curve of the thermoelectric cooling modules,peltier cooler,TEC modules .

Post time: Nov-13-2023