Since 2025, Thermoelectric Cooling (TEC) technology has made remarkable progress in materials, structural design, energy efficiency and application scenarios. The following are the latest technological development trends and breakthroughs at present

I. Continuous optimization of core principles

The Peltier effect remains fundamental: by driving N-type/P-type semiconductor pairs (such as Bi₂Te₃ -based materials) with direct current, heat is released at the hot end and absorbed at the cold end.

Bidirectional temperature control capability: It can achieve cooling/heating simply by switching the current direction, and is widely used in high-precision temperature control scenarios.

II. Breakthroughs in material properties

1. New thermoelectric materials

Bismuth telluride (Bi₂Te₃) remains the mainstream, but through nanostructure engineering and doping optimization (such as Se, Sb, Sn, etc.), the ZT value (optimal value coefficient) has been significantly improved. The ZT of some laboratory samples is greater than 2.0 (traditionally about 1.0-1.2).

Accelerated development of lead-free/low-toxicity alternative materials

Mg₃(Sb,Bi)₂ -based materials

SnSe single crystal

Half-Heusler alloy (suitable for high-temperature sections)

Composite/gradient materials: Multi-layer heterogeneous structures can simultaneously optimize electrical conductivity and thermal conductivity, reducing Joule heat loss.

III, Innovations in the structural system

1. 3D Thermopile design

Adopt vertical stacking or micro channel integrated structures to enhance the cooling power density per unit area.

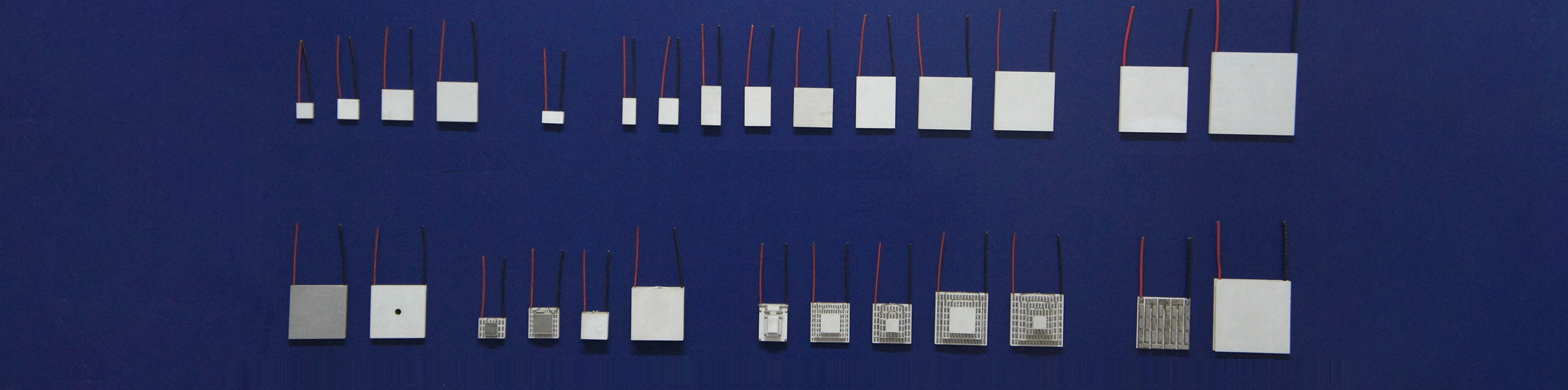

The cascade TEC module, peltier module,peltier device, thermoelectric module can achieve ultra-low temperatures of -130℃ and is suitable for scientific research and medical freezing.

2. Modular and intelligent control

Integrated temperature sensor + PID algorithm + PWM drive, achieving high-precision temperature control within ±0.01℃.

Supports remote control via the Internet of Things, suitable for intelligent cold chain, laboratory equipment, etc.

3. Collaborative optimization of thermal management

Cold end enhanced heat transfer (microchannel, phase change material PCM)

The hot end adopts graphene heat sinks, Vapor chambers or micro-fan arrays to solve the bottleneck of “heat accumulation”.

IV, application scenarios and fields

Medical and health care: thermoelectric PCR instruments, thermoelectric cooling laser beauty devices, vaccine refrigerated transport boxes

Optical communication: 5G/6G optical module temperature control (stabilizing laser wavelength)

Consumer electronics: Mobile phone cooling back clips, thermoelectric AR/VR headset cooling, peltier cooling mini refrigerators, thermoelectric cooling wine cooler, car refrigerators

New energy: Constant temperature cabin for drone batteries, local cooling for electric vehicle cabins

Aerospace technology: thermoelectric cooling of satellite infrared detectors, temperature control in the zero-gravity environment of space stations

Semiconductor manufacturing: Precision temperature control for photolithography machines, wafer testing platforms

V. Current Technological Challenges

The energy efficiency is still lower than that of compressor refrigeration (COP is usually less than 1.0, while compressors can reach 2-4).

High cost: High-performance materials and precise packaging drive up prices

The heat dissipation at the hot end relies on an external system, which limits the compact design

Long-term reliability: Thermal cycling causes solder joint fatigue and material degradation

VI. Future Development Direction (2025-2030)

Room-temperature thermoelectric materials with ZT > 3 (Theoretical limit breakthrough)

Flexible/wearable TEC devices, thermoelectric modules,peltier modules (for electronic skin, health monitoring)

An adaptive temperature control system combined with AI

Green manufacturing and recycling technology (Reducing Environmental Footprint)

In 2025, thermoelectric cooling technology is moving from “niche and precise temperature control” to “efficient and large-scale application”. With the integration of materials science, micro-nano processing and intelligent control, its strategic value in fields such as zero-carbon refrigeration, high-reliability electronic heat dissipation and temperature control in special environments is increasingly prominent

TES2-0901T125 Specification

Imax:1A,

Umax:0.85-0.9V

Qmax:0.4 W

Delta T max:>90 C

Size : Base size :4.4×4.4mm, top size 2.5X2.5mm,

Height: 3.49 mm.

TES1-04903T200 Specification

Hot side temperature is 25 C,

Imax: 3A,

Umax:5.8 V

Qmax: 10 W

Delta T max:> 64 C

ACR:1.60 Ohm

Size: 12x12x2.37mm

Post time: Dec-08-2025